At 6:47 a.m. on June 6, 1944, the first wave of landing craft reached Omaha Beach. The steel ramps dropped. The men rushed forward under German machine-gun fire. Within 12 minutes, the beach was stained red, but the boats kept coming, wave after wave. 31,000 men landed in the first six hours. None of them knew that the craft carrying them ashore had been built in a swamp three years earlier by workers who had never seen the ocean.

This is the story of how 20,000 Louisiana workers built 23,000 landing craft and won the war before a single American soldier set foot on European soil. The problem began in 1940, a year before Pearl Harbor. The U.S. military faced a tactical nightmare that no one wanted to admit. Every invasion plan required one thing.

One way to land thousands of troops directly on hostile beaches. Traditional landing methods didn’t work. Ships anchored offshore. Men were lowered by rope nets into small boats. The boats were then rowed to the beach. The process took hours. The German defenders had hours to prepare. Men died in the water before reaching land.

The Navy examined all available options. British landing craft were too slow. Civilian fishing boats were too fragile. Purpose-built assault craft would take years to design. By the time engineers finished the plans, the war would be over. Invading Europe required vessels that didn’t exist.

The army needed 10,000 of them, maybe more. Nobody knew how to build them. Nobody knew who could build them. And they needed them within two years.

In New Orleans, a 45-year-old boat builder named Andrew Jackson Higgins read the military requirements. He didn’t apply through the proper channels. He didn’t wait for an invitation. He wrote directly to the Navy’s Bureau of Ships. His letter contained one sentence:

—I’ve already built what they need.

Higgins wasn’t exaggerating. For 15 years, he had designed shallow-draft boats for oil companies working in the Louisiana swamps. His boats could navigate in water as shallow as 18 inches. They could climb onto muddy banks, lower a ramp, unload equipment, reverse from the shore, and return to deep water. The oil companies loved them. The military had never heard of them. Higgins invited Navy observers to New Orleans.

He demonstrated his boat on Lake Pontchartrain. The vessel approached the shore at full speed. The bow struck the sand. The engine reversed. A steel ramp dropped from the bow. The men walked straight down onto the beach. The ramp retracted. The boat backed into the water and sped away. Total time: 42 seconds. Navy officers watched in silence.

One of them asked how quickly the boat could be produced. Higgins looked at the lake, looked back at the officers, and then said something that should have sounded like madness:

—I can build 1,000 per month if I get the contracts.

The Navy didn’t believe him. Higgins Industries employed fewer than 300 people. The company operated two small shipyards. Its largest government contract had been for 12 patrol boats. Now, Higgins claimed it could produce 1,000 landing craft every 30 days. The numbers didn’t add up. The infrastructure didn’t exist. But the military had no alternative. In August 1941, four months before Pearl Harbor, the Navy authorized a trial order: 50 landing craft.

Higgins had 90 days to deliver them. They delivered them in 73 days. Every boat passed inspection. The Navy ordered 500 more, then 1,000, then 5,000. By the time the Japanese bombed Pearl Harbor, Higgins Industries had contracts for 8,000 landing craft. The question was no longer whether the boats could be built.

The problem was where to build them. New Orleans in 1941 had no industrial shipyards. The city had wharves, warehouses, and repair facilities. It had fishing boats and cargo ships. It had no assembly lines. It had no skilled welders. It had no industrial cranes or steel rolling mills, nor the electrical capacity to power them.

Higgins looked at a city map and found seven locations near the industrial canal. Swamps, vacant lots, fishing piers—places no one wanted. He leased them all. By January 1942, construction crews were draining swamps and pouring concrete foundations. By March, the first assembly buildings were going up.

By May, the factories were operational. Higgins Industries now occupied 110 acres along the industrial canal: eight separate plants. Each plant specialized in a different phase of production. Plant one manufactured steel hulls. Plant two installed engines. Plant three built ramps and hydraulic systems. Plant four handled electrical wiring.

Plant five applied waterproofing and painting. Plant six tested the completed vessels in an artificial basin. Plants seven and eight handled repairs and modifications. The process was not traditional shipbuilding. Higgins borrowed techniques from the automotive industry: assembly line production, standardized parts, modular construction.

Each landing craft was divided into 12 main sections. Each section moved along a separate line. The sections converged at the final assembly. Welders joined them into a complete hull. The hull moved to the next station. Engines arrived from Wisconsin. Ramps arrived from Pennsylvania. Radios arrived from New Jersey.

By the time a boat reached the end of the line, 387 workers had touched it. None of them saw the finished boat until it was complete. The workforce grew faster than the factories. Higgins hired anyone willing to learn. Former fishermen became welders. Typists became crane operators. High school teachers became electrical engineers.

The company trained them in two-week programs. No prior experience was required. Just show up on time and follow instructions. By the end of 1942, Higgins Industries employed 14,000 workers. A year later, the number reached 20,000. Forty percent of them were women. Fifteen percent were Black workers hired at a time when most defense contractors refused to employ them.

The factories operated 24 hours a day, in three eight-hour shifts. The day shift began at 6:00 a.m. The afternoon shift began at 2:00 p.m. The night shift began at 10:00 p.m. The shift changes resembled a small town changing its population. Thousands of workers leaving. Thousands arriving. The gates never closed. The assembly lines never stopped.

Sparks from welding torches fell on three separate floors simultaneously. Inside floor one, the steel hull assembly line stretched 300 feet beneath a corrugated steel roof that trapped heat like an oven. Summer temperatures inside reached 115°F. Winter brought no relief, only different problems.

Condensation dripped from the ceiling onto the hot metal, creating clouds of steam that obscured visibility. The workers learned to navigate by sound and memory. A flatbed railcar delivered steel plates cut to precise dimensions to a steel mill in Pennsylvania. The plates arrived wrapped in oil-soaked paper to prevent rust during transport. The workers unwrapped them with gloved hands.

The steel was 3/8 inch thick for the hull, 1/4 inch for the ramp, and 5/8 inch for the bow, which would bear the brunt of the impact. Each plate weighed between 100 and 300 pounds, depending on its position on the vessel. Overhead cranes lifted the plates onto assembly jigs specifically designed for landing craft production. The jigs held the steel at precise angles while welders secured them in place.

The welding teams worked in pairs. One operator handled the arc welder. The second positioned the next plate. They alternated every 20 minutes to prevent arm fatigue. A fatigued welder made mistakes. Mistakes meant leaks. Leaks meant drownings. The welding process created its own environment. The arc flash burned bright enough to blind. Sparks rained down.

The ozone from the electric arc mixed with the metal fumes, creating a smell that clung to clothing and hair. Workers wore leather aprons, thick gloves, and dark-tinted masks. Even with protection, burns were common, mostly minor—the occasional spark that found skin between a glove and a sleeve.

The flash burn caught a bare neck. Medical stations were positioned every 50 feet along the assembly line. A team of riveters followed behind the welders, reinforcing critical joints. Pneumatic hammers drove steel rivets through pre-drilled holes. The noise was extraordinary. A single hammer produced 110 dB. Twenty hammers working simultaneously created a sound pressure that vibrated through the bone.

The workers wore cotton wool stuffed in their ears. Some lost their hearing anyway. By 1943, partial deafness had become so common among the riveters that the company installed visual signaling systems alongside the audible ones. The hammers struck in rhythm. Three blows per rivet. Thousands of rivets per vessel. The sound became their own language.

Experienced workers could tell by listening whether a rivet was properly set. A dull thud meant good contact. A metallic ring meant the rivet hadn’t fully seated. Misplaced rivets were drilled out and replaced. No exceptions. Military inspectors checked random samples. If they found bad rivets, they rejected the entire vessel.

A complete hull frame emerged from the line every 37 minutes. Cranes lifted it onto a wheeled trolley. The trolley rolled along steel rails toward Plant 2. The track system connected all eight plants, creating a continuous flow of components and completed sections. The tracks measured 7 miles in total, winding through the factory complex like an industrial railway.

On floor 2, the engine installation teams worked in pairs under conditions that made floor one seem comfortable. The engine compartment measured 4 feet by 6 feet. Two men had to work in that space simultaneously. One mechanic positioned the engine. The second bolted it to the engine mounts. The engine weighed 480 pounds.

Moving it required a small overhead hoist and precise coordination. If you dropped it wrong, you’d crush your partner’s foot. If you positioned it incorrectly, the driveshaft wouldn’t align. The engines came from Gray Marine Motor Company in Detroit. They were modified versions of the Chrysler flathead six-cylinder engine used in civilian trucks.

The modification involved waterproofing the electrical system and adding a heavy-duty cooling system capable of operating in saltwater. Each engine produced 125 horsepower at 2,800 RPM. Not very powerful by boating standards, but reliable. Reliability mattered more than speed. The fuel lines connected from the tank to the carburetor using reinforced rubber hoses secured at both ends.

The cooling systems were connected to a heat exchanger that used seawater as a coolant. The seawater intake valve had to be positioned exactly 3 inches below the waterline. Too high and it would suck in air during rough seas; too low and it would drag the bottom in shallow water. The margin of error was less than an inch. The throttle cables were threaded through the steering console using a conduit system that protected them from water and damage.

The cables measured exactly 17 feet 3 inches from the throttle grip to the carburetor. Any shorter and they would tighten during sharp turns; any longer and they would develop slack, making precise speed control impossible. The measurements had been determined through testing. Now they were standard. Every boat built exactly the same way. Electrical wiring ran from the battery to the ignition, to the navigation lights, to the radio system, to the bilge pump.

247 feet of cable per boat. Each cable color-coded, each connection soldered and wrapped in waterproof tape. The electrical systems had to function after a full submergence. The military tested this by sinking boats in training pools, then hauling them out and attempting to start them up.

If the engine failed to start on the first attempt, the vessel failed inspection. The entire installation process took 1 hour and 42 minutes per vessel under normal conditions. Any longer and the line would jam. Plant three could not begin work until plant two finished. Plant four could not begin until plant three completed its section.

Time cascaded through the entire factory. A delay in engine installation meant delays in ramp assembly, hydraulic testing, electrical installation, and final painting. A 30-minute slowdown on Plant 2 created a three-hour bottleneck by the end of the day. The pressure to keep pace was constant. Supervisors walked the line with stopwatches. They didn’t shout.

They didn’t need to. Everyone understood the math. Slower work meant fewer boats. Fewer boats meant men dying while waiting for transport that never came. The workers pushed themselves harder than any supervisor could have demanded. Mistakes were inevitable. A weld cracked under stress.

A bolt would loosen during engine testing. A hydraulic line would leak under pressure. Inspectors caught most of the problems before the boats left the factory. Some they didn’t. Some boats broke down during training exercises. Some failed during actual landings. The army tracked failure rates, filed reports, and demanded repairs. Higgins responded by adding inspection stations.

By early 1943, each landing craft underwent 14 separate quality control checks before delivery. Quality control became its own department. Inspectors carried clipboards and measuring tools. They checked weld integrity, measured ramp angles, tested hydraulic pressure, and verified engine compression. If a craft failed any test, it was returned to the appropriate station.

The team responsible for the error fixed it. No exceptions, no appeals. A landing craft either met specifications or it didn’t. Men would die if the boats failed. The inspectors never forgot that. Production numbers increased throughout 1943. In January, the factories completed 670 landing craft. By March, the number had reached 800. By June, it had climbed to 1,000.

The Navy increased orders. The Army requested a modified version with thicker armor. The Marines wanted boats capable of carrying tanks. Higgins redesigned the boats without halting production. The assembly lines were adapted in real time. New components arrived. New procedures were printed. The workers learned the modifications on the job.

The army designated different models for different purposes. The LCVP, Landing Personnel Vehicle, carried 36 soldiers or a jeep. The LCM, Mechanized Landing Craft, carried a 30-ton Sherman tank. The LCI, Infantry Landing Craft, carried 200 troops. The LCT, Landing Craft Tank, carried four Sherman tanks.

Higgins Industries built them all. By the end of 1943, the factories had produced 12,000 boats. The company became the largest private employer in Louisiana. The workers didn’t know where the boats were going. They knew the war was happening. They knew men were dying. They didn’t know about D-Day. Nobody did. The invasion plans remained classified until three days before the landings.

But inside the factories, the workers understood what was at stake. Every weld mattered. Every bolt mattered. If a ramp jammed, men would die in the water. If an engine failed, soldiers would drown before reaching the beach. The work wasn’t abstract. It was life or death etched in steel and rivets. Women made up nearly half the workforce.

Most had never worked outside their homes before the war. Now they operated pillar drills, arc welders, and hydraulic hoists. They wore overalls and steel-toed boots. They worked 10-hour shifts in 100° heat. Welding masks hid their faces. Sparks burned through their sleeves. Some worked alongside their husbands.

Some worked while their husbands fought overseas. None of them complained. The work was hard. The pay was decent. The purpose was clear. Black workers faced different challenges. Many had been barred from industrial jobs before the war. Unions resisted hiring them. White workers threatened strikes. Higgins ignored the threats.

He needed workers. He didn’t care about skin color. He cared about production. By 1943, 3,000 Black workers were employed at the plants. They worked the same shifts, earned the same wages, and used the same cafeterias as the white workers. In a segregated South, Higgins Industries became one of the most integrated factories in the country.

The integration wasn’t perfect. There were tensions, arguments erupted. Some workers quit rather than share a workspace. Higgins responded by threatening to fire anyone who disrupted production. The policy was simple: work together or leave. Most of the workers stayed. They had families to feed, bills to pay. The war wouldn’t stop because of personal prejudices.

Neither did the assembly lines.

By early 1944, the factories had reached their peak production rate: 1,200 landing craft per month, 40 boats per day, one every 36 minutes. The industrial canal was filled with newly finished boats. They floated in rows side by side, waiting for transport. Navy crews arrived weekly to collect them. Tugboats took them in groups of 20 to the Mississippi River. From there, they traveled to staging areas on the Gulf Coast, then across the Atlantic to Europe, to beaches no one in New Orleans had ever seen.

On June 5, 1944, the workers inside the Higgins factories finished their shifts and went home. They didn’t know that the invasion would begin the next morning. They didn’t know that 12,000 landing craft were already positioned off the coast of Normandy. They didn’t know that 156,000 Allied soldiers would rely on those craft to reach the beaches.

The workers went home, slept, and returned to their shifts the next day. The assembly lines kept running. The war required more boats. More boats required more workers. The cycle continued. At 6:30 a.m. on June 6, the first wave was launched from transport ships 12 miles off the French coast. The landing craft formed lines, 31 boats per line, eight lines in total.

248 boats in the first assault wave. Behind them, three more waves awaited their turn. Behind those, hundreds more waited, ready to follow. The engines rumbled at idle, creating a mechanical growl that rolled through the water. Waves crashed over the bows, sending spray down on the soldiers huddled below deck. The channel was choppy that morning. Swells of 3 to 4 feet.

Northeast wind at 15 knots. Visibility of 4 miles through scattered rain and fog. The conditions weren’t terrible, but they weren’t good either. Inside the boats, the soldiers sat shoulder to shoulder on wooden benches bolted to the hull. 36 men per boat, full combat gear, rifles, ammunition, grenades, gas masks, ration packs.

Some carried Bangalore torpedoes to clear barbed wire obstacles. Some carried radios that weighed 30 pounds. Some carried medical supplies. The total weight per soldier averaged 80 pounds. The total weight per boat exceeded three tons before adding fuel and crew. Most of the soldiers had never been in combat. Most were between 18 and 22 years old. Most were from small towns across the United States.

They trained for months, practiced landings on beaches along the English coast, studied maps of the French coastline, and memorized unit objectives. But training never prepared anyone for the reality of sailing toward enemy fire, knowing there was no turning back. The boats pushed through the surf toward the shore. Each wave lifted the bow, then dropped it into the valley below.

The steel hulls slammed against the water loud enough to ring like bells. Inside, the men braced themselves for the impacts. Some gripped the edges of the bench. Some held their rifles. Some closed their eyes and prayed silently. Conversation was impossible over the roar of the engine and the constant pounding of the waves against the hull.

Seasickness affected almost everyone. The combination of diesel fumes, the movement of the waves, fear, and adrenaline created nausea that overwhelmed even the strongest stomachs. Soldiers vomited in their helmets, their backpacks, and on their boots. The smell mingled with diesel, salt spray, and fear. Some soldiers had been on transport ships for 16 hours before boarding the landing craft.

They had been sick before the boats had even been launched. Now, 12 miles from shore, they were more than sick. They were exhausted, dehydrated, and terrified. German defenders watched from fortified positions on the cliffs. They had been watching since before dawn. Radar had detected the invasion fleet hours earlier. The artillery crews were ready at their guns.

The machine gun positions were manned and loaded. The beach stretched flat and empty between the waterline and the seawall. 400 yards of open sand with zero cover. The defensive plan was simple. Let the boats reach the beach, wait for the ramps to drop, then open fire. Maximum casualties in minimum time.

The landing zone, designated Omaha Beach, stretched six miles along the Normandy coast. The beach was divided into five sectors, each with its own code name: Charlie, Dog Green, Dog White, Dog Red, Easy Green, Easy Red, and Fox Green. The first wave would hit all sectors simultaneously at H-hour, 6:30 a.m. Follow-up waves would land every 10 minutes for the first three hours.

At 6:35 a.m., 500 yards from shore, the helmsmen pushed their throttles forward. The engines roared from idle to full power, 2,800 RPM. The boats accelerated from 8 knots to 11 knots—maximum speed for the conditions. The bows lifted slightly as the hulls glided through the swell. Spray shot 20 feet into the air on either side of each vessel.

At 400 yards, the German artillery opened fire. The first shells fell short, exploding in the water 50 yards ahead of the lead boats. Columns of white water erupted into the sky. The next salvo fell closer. A shell struck a boat in the second wave. A direct hit. The boat exploded. Debris flew out. Men were thrown out. The boat sank in less than 20 seconds.

Thirty-six soldiers and three crew members were missing before reaching the beach. At 300 yards, machine guns joined the artillery. MG42s were firing from concrete bunkers at 1,200 rounds per minute. The sound was distinctive, a mechanical drone that carried through the water like chainsaws. Tracer rounds arced through the rain and fog in bright horizontal lines.

Most of the rounds passed overhead. Some struck the hulls with cracked metal. The steel held. The boats kept coming. At 200 yards, the German fire intensified. More machine guns, more artillery, mortars now. The beach erupted in explosions and muzzle flashes. The noise became overwhelming: artillery booming, machine guns chattering, shells screaming, water exploding.

The soldiers inside the boats heard everything and saw nothing. They sat in the dark bellies of steel hulls, sailing toward sounds that promised death. At 100 yards, the helmsmen began assessing the landing points. The beach ahead revealed obstacles that aerial reconnaissance had missed: wooden stakes driven into the sand, steel rails welded to barbed wire, concrete barriers, some topped with mines.

The obstacles ran in rows parallel to the shore, spaced to catch boats at different tidal levels. Helmsmen had to weave between them or risk hitting mines that would blow off the bow. At 50 yards, individual German soldiers became visible in their positions: men behind machine guns, men loading mortars, men preparing grenades. Some of the defenders were teenagers.

Some were veterans of the Russian front. All of them fired on the approaching boats with everything they had. At 6:47 a.m., the first landing craft reached Omaha Beach. The time was recorded in multiple post-action reports filed by surviving officers. The exact minute mattered because each subsequent wave timed its landing against that first touch.

H+17 minutes, H+27 minutes. Military operations were running with precise timing, even as everything else descended into chaos. The vessel designated LCI 475 touched down first, hitting sand in the Dog Green sector directly in front of Vierville’s beach exit. The helmsman cut the engine.

The bow scraped forward another 10 feet before stopping. The craft sat in 3 feet of water 60 yards from dry sand. The hydraulic system activated. The ramp began to descend. Steel scraped against steel. The ramp dropped through its arc. As the ramp lowered, it exposed the men inside to direct fire. Machine gun rounds pierced through the opening before the ramp touched the water.

The soldiers in the front row were hit while still standing inside the boat. They fell forward. The men behind them had nowhere to go except forward over the bodies. The ramp hit the water. Thirty-six soldiers ran forward under machine-gun fire that couldn’t miss. The distance from the ramp to the German positions was 280 yards.

The maximum effective range for an MG42 was 800 yards. The gunners didn’t need to aim carefully. They simply fired in sweeping arcs across the ramp area. Bullets hit the water, hit the men, hit the equipment, hit everything. Men fell into the water. The weight of their gear pulled them down. 80 pounds of equipment. Boots full of water.

Soaked uniforms. Arms couldn’t fight the weight. Some soldiers drowned in three feet of water without ever seeing the beach. Some reached the sand and were beaten while running for the seawall. Some reached the seawall and found temporary cover. Most didn’t make it at all. The boat backed away from the beach.

The ramp retracted. The helmsman reversed the engine and backed into deeper water. The entire process, from the ramp’s deployment to departure, took 43 seconds. In that time, 22 soldiers were killed and 11 wounded. Three reached the seawall alive. The vessel turned around and headed back to the transport ships to pick up the next cargo.

248 landing craft reached the beach in the first wave. The experience of LCI 475 was repeated in all five sectors with minor variations. Some craft struck mines and exploded. Some successfully ran aground but suffered casualties in the race to the seawall. Some landed in the wrong sector and encountered weaker defenses. Some landed directly under the heaviest guns and lost everyone.

The casualty rate in the first wave exceeded 60% in some units. By 7:15 a.m., 2,000 Americans were dead or wounded on Omaha Beach, but the boats kept coming. Every 10 minutes, another wave, another 200 boats. The Germans couldn’t stop them all. They couldn’t cover every sector simultaneously. They couldn’t reload fast enough.

They couldn’t see through the smoke from their own weapons. The sheer volume of targets overwhelmed the defenses. Some boats managed to get through. Some soldiers reached the seawall. Some units pushed forward toward the cliffs. The defenses that had seemed impenetrable began to crack. By 9:00 a.m., 16,000 soldiers had landed on Omaha Beach.

Half were combat-ready. Half were casualties or suppressed by fire, but 16,000 was enough. Enough to establish a foothold, enough to push inland, enough to force the Germans to commit reserves, enough to prove that the landing could succeed despite casualties. The landings continued throughout the day, boat after boat, wave after wave.

By nightfall, 34,000 troops had crossed the beach. Tanks rolled out of LCTs directly onto the sand. Artillery pieces arrived in LCMs and took up firing positions. Supply trucks rolled out of LCVPs and began transporting ammunition to the forward units. The invasion that military planners had feared would fail was succeeding.

Slowly, bloodily, but successfully. The Higgins boats made it possible. They kept coming despite the fire, despite the casualties, despite the mines and obstacles and machine guns. The helmsmen steered them straight toward the guns because that was the job. The ramps dropped because the hydraulic systems worked. The engines worked because the mechanics in Louisiana had installed them correctly.

The helmets held because the welders at Plant One had done their work with precision. Every technical decision made in factories 3,000 miles away affected whether the men lived or died on Omaha Beach. The landings continued for three days. Each day brought more boats, more men, more equipment. By June 9, 156,000 Allied troops had crossed the Channel and landed in France.

Tanks rolled out of the LCTs directly onto the sand. Artillery pieces arrived in LCMs. Supply trucks disembarked from LCVPs and drove up the beach roads. The invasion that military planners said couldn’t happen was happening. The boats made it possible. Not all the boats survived. German artillery sank dozens. Mines destroyed more.

Rough seas capsized some of the boats before they reached the beach. The failure rate was around 8%. That meant 92% were successful. In military terms, that was exceptional. In human terms, it meant thousands of soldiers reached the shore alive who would have drowned using any other method. The Higgins boats didn’t win the war on their own, but they gave the invasion a chance to succeed.

Without them, D-Day would have failed. Inside the Higgins factories, the workers learned of the invasion from newspapers and radio broadcasts. They heard casualty reports. They heard about the beach landings. They understood for the first time what the boats were for. Some workers wept. Some felt pride.

Some were horrified by the deaths. Most simply returned to their shifts. The war wasn’t over. More landings were coming. The Pacific theater required thousands of additional vessels. The Philippines, Iwo Jima, Okinawa. Every island invasion needed boats. The factories kept producing them. By the end of 1944, Higgins Industries had built 20,000 landing craft.

The company also manufactured torpedo boats, patrol vessels, and even experimental amphibious vehicles. The workforce exceeded 23,000. The factories consumed 15 tons of steel per day. Electricity bills surpassed €50,000 per month. The industrial canal, once a quiet backwater, became one of the most productive shipyards in the world.

All of this was built on marshy land reclaimed by workers who had never built a warship before the war began. Production slowed in 1945 as the war drew to a close. Contracts were cut back. Workers were laid off. By September, when Japan surrendered, the factories were operating at 20 percent capacity. The military no longer needed landing craft. Victory eliminated the demand.

Within six months, most of the plants had closed. The workers found other jobs. The assembly lines fell silent. The steel rusted, the paint faded. The boats that once filled the canal disappeared into storage or scrapyards. Andrew Jackson Higgins did not live to see the end of the war reshape his empire. He died in 1952, seven years after the factories closed.

The company went bankrupt. The plants were sold off piecemeal. The land reverted to industrial use. Most of the buildings were demolished by 1960. Today, almost nothing remains of the factories that built the boats that won the war. A historical marker stands near the site. A small museum preserves a few artifacts, but the swamp has reclaimed most of the land.

The canal flows serenely past rusted pilings and empty lots where 20,000 workers once built history, one weld at a time. General Dwight Eisenhower, Supreme Commander of the Allied forces in Europe, later said that Andrew Jackson Higgins was “the man who won the war for us.” Eisenhower didn’t say that about generals or admirals.

He said it about a New Orleans shipbuilder. A man who looked at a swamp and saw a shipyard. A man who hired workers no one else would. A man who believed speed of production mattered more than tradition. The 20,000 workers never received medals. They didn’t march in victory parades. Most never saw the ocean.

They built boats in a swamp and sent them to war. They worked eight-hour shifts in 100-degree heat. They welded steel until their hands blistered. They operated machinery until their backs ached. They knew men were dying. They knew their work mattered. That knowledge kept them returning to the factories every day for four years.

On Omaha Beach today, tourists walk the sand where soldiers died. Memorials mark the landing zones. Flags flutter above the cliffs. The beach is quiet now. The war ended 80 years ago. But beneath the tranquil surface, history recalls the steel ramps that tumbled down, the engines that roared, the boats that carried men into machine-gun fire. Those boats came from Louisiana.

They came from workers who had never seen combat. They came from factories built in 90 days on land that used to flood every spring. They came from a belief that impossible things become possible when ordinary people refuse to accept failure. 23,000 landing craft built by 20,000 workers. Most of them are gone now. The workers died decades ago. The factories disappeared.

The boats sank, rusted, or were cut up for scrap. But their contribution remains. Every D-Day story mentions the landing craft. Every account of the invasion acknowledges their importance. Yet few people know where they came from. Few people know about the swamps of New Orleans. Few people know about the men and women who built them.

This is their story. Not the story of generals or battles. Not the story of strategy or tactics. The story of production. The story of the workers. The story of what happens when ordinary people are given extraordinary responsibility and refuse to fail. The story of how wars are won not only on battlefields, but in factories, on assembly lines, in the hands of welders and riveters and crane operators who never fired a shot. The boats are gone.

The workers are gone. The factories are gone. But the memory remains. Steel and sweat and 20,000 people who built the ships that carried 156,000 soldiers to the beaches of Normandy. That memory does not fade. It resonates forward through time. A reminder that history is not made by those who fight alone.

It is made by those who build, those who work, those who weld, those who refuse to let impossibility define the limits of what can be done. That is the legacy of the Higgins factories, not just the boats, not just the invasion. The idea that ordinary people, given a purpose and a deadline, can change the course of history. The idea that a swamp in Louisiana can become the birthplace of victory.

The idea that war is won not only with courage but with production, precision, and the relentless determination of workers who understand that every weld, every bolt, every completed vessel brings the end of the war one step closer. The sun rises over the industrial canal today. The water flows calmly past abandoned docks.

Weeds grow where assembly lines once stood. No marker identifies the exact locations of Plant One or Plant Two. No monument honors the welders. No statue commemorates the crane operators. But the work they did remains embedded in history. It remains etched in the story of how the war was won. It remains in the archives, the photographs, the after-action reports that describe the landings in precise technical detail.

23,000 landing craft built by 20,000 workers in four years on reclaimed swampland for a war most of them never saw. That’s not just a production statistic. That’s proof of what happens when purpose meets ability. When necessity meets determination, when a nation asks its workers to do the impossible, and they respond by making history one boat at a time, those boats carrying soldiers to the beaches.

The workers bore the weight of knowing that men’s lives depended on their precision. Both succeeded. Both are remembered. One in memorials and ceremonies, the other in stories like this. Stories that insist on remembering not only the battles, but the infrastructure that made them possible. Stories that refuse to let time erase the contribution of those who built the machines that changed the world.

News

During an elegant charity gala, my wife quietly looked past my modest profession, unaware that the evening’s guest of honor would soon recognize me as someone who had once helped shape his path. The moment subtly changed the atmosphere, serving as a quiet reminder that a person’s true value is never measured by titles or appearances.

I stood in the far corner of the Diamond Lip Ballroom, holding a silver tray stacked with half-eaten appetizers, my…

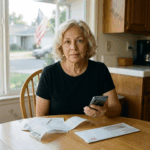

My daughter-in-law often misjudged me, never realizing I was the one quietly paying for the house, the car, and our monthly expenses. Rather than explaining myself or starting conflict, I chose to remain calm and make a personal financial decision—one that gradually reshaped our family’s expectations and her understanding of independence.

My daughter-in-law laughed at me at the dinner table without even lowering her voice. “Besides being poor, you’re useless.” The…

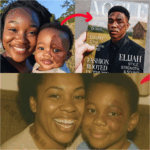

I made a difficult decision to close my mother-in-law’s high-end credit account after realizing she was involved in a personal situation that deeply affected my marriage. While she continued enjoying expensive shopping paid for with shared resources, I chose to quietly regain my footing and restore balance in my life, knowing that her comfortable lifestyle and long-standing financial arrangements were slowly but inevitably changing.

I canceled my mother-in-law’s credit card after discovering she was shopping with my husband’s mistress. While my mother-in-law helped my…

Jesus’ Tomb Opened After 2000 Years, What Scientists Discovered Shocked the Entire World

In a groundbreaking development that has sent shockwaves around the globe, scientists have opened Jesus Christ’s tomb for the first…

BREAKING NEWS: Keanu Reeves once revealed what makes him happy—and fans say it’s the purest answer ever ⚡

Keanu Reeves Once Revealed What Makes Him Happy—and Fans Still Call It the Purest Answer Ever Keanu Reeves has starred…

BREAKING NEWS: Keanu Reeves shares romantic kiss with Alexandra Grant in rare NYC date night moment

Keanu Reeves Shares Passionate Kiss With Girlfriend Alexandra Grant—and Fans Say, “Love Looks Exactly Like This” Keanu Reeves doesn’t chase…

End of content

No more pages to load